RS Breather At Earnhardt Case Study

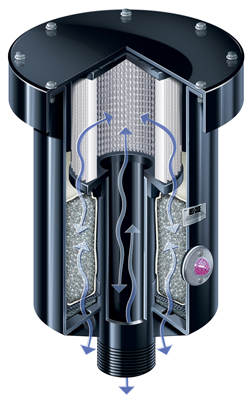

Rebuildable Steel Breathers Earnhardt-Childress Racing

CustomerEarnhardt –Childress Racing (ECR) Welcome, North Carolina |

IndustryMotorsports |

Company Profile

Earnhardt-Childress Racing, located in Welcome, NC, is a leader in the development of motorsports engines for Chevrolet NASCAR Cup, Nationwide, and Truck Series. With 120 dedicated employees and 62,000 sq ft, ECR produces over five hundred groundbreaking engines annually and earned (50) race victories 2010. They have redefined what it means to be a racing champion.

Website

Products Used

The Des-Case solution was intuitively engineered and the serviceability was best in class when compared to other options.

The Challenge

When NASCAR mandated the 15% ethanol-gasoline blend starting with the Daytona 500, in an attempt to increase green and environmentally friendly applications, it proposed an entirely different challenge for companies who supply racing engines in the NASCAR circuit.

The most problematic being the fact that ethanol is hygroscopic, readily absorbing water from the air and essentially altering the fuel mixture and compromising the purity and strength of the engine fuel.

As testing proceeded, it was quickly realized that for every 1% of water that the ethanol pulled into the fuel storage tank the engine would lose 10 hp.

In a world where speed determines the champion and every horsepower counts, ECR took immediate action to find a solution that would protect their fuel from the moisture that could ultimately negate their tireless hours of research, development, and testing.

Recent Comments