Specifications

Operational Parameters

| Fluid Compatibility / Corrosion Resistance | Hydrocarbon based & Synthetic hydraulic fluids |

| Min Inlet Pressure | positive pressure |

| Max Inlet pressure | 50 bar (pump option dependent) |

| Max Outlet pressure | 6 bar (pump option dependent) |

| Max Fluid Temperature (Continuous) | Max. 80 °C viscosity dependent. Not lower than 10 cSt |

| Min Fluid Temperature (Continuous) | Viscosity dependent. Not greater than 1.000 cSt |

| Min Temperature (Start Up) | Viscosity dependent. Not greater than 1.000 cSt ≈ 25 °C ISO VG 320 |

| Max Viscosity | 1,000 cSt |

| Min Viscosity | 10 cSt |

| Min Start Up Ambient Temperature | -30° C |

| Max Continuous Ambient Temperature | 65° C |

| Power Consumption | 0.25 kW max |

| Weight | 13 kg |

Features

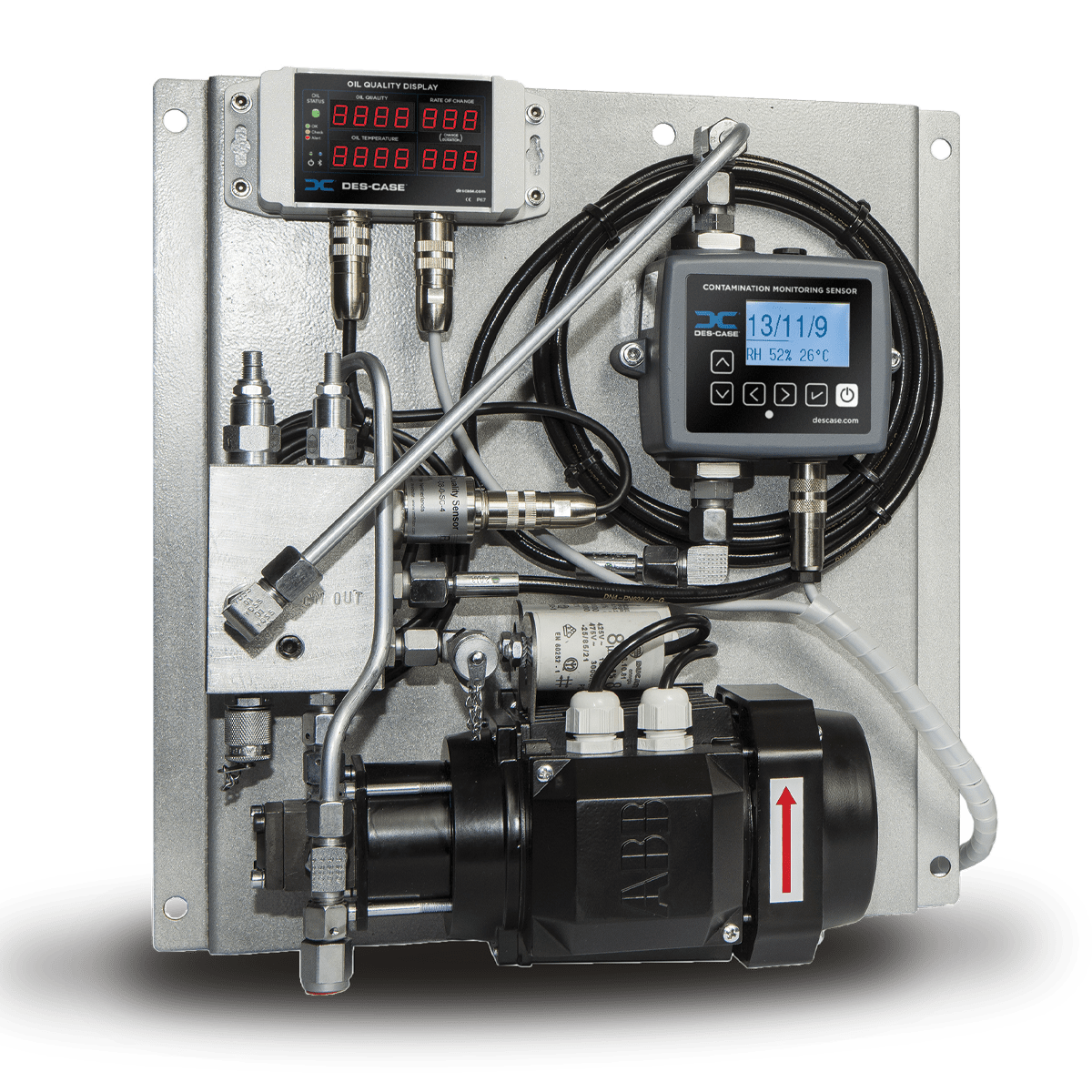

The CMC can be installed in most low pressure hydraulic and lubrication systems ranging from zero bar pressure to a max of 50 bar on the inlet of the system. A further option can be installed on systems with a max of 0,5 bar on inlet of CMC pump and a max of 6 bar on system return. These two options give the user the versatility to install the CMC in a variety of different system applications. Also the Condition Monitoring Center can be designed with an integrated magnetic coupling. This option can handle inlet pressures of 25 bar and 25 bar pressure on the outlet of the unit. Utilizing the best particle counter in its class as standard, the CMC delivers simplicity, practicality & accuracy for the most demanding of applications. Proven optical technology and algorithms ensure consistent monitoring of your system, providing peace of mind for your operators.

- Renewable energy

- Gearbox applications

- Automotive industry

- Paper industry

- Offshore systems

- Lubrication systems

- Marine thrusters

- Test Benches

- Entrained air or turbulent flows

- Higher viscosity fluids

- Un-pressurized systems

- Reliable & accurate performance.

- Allows for proactive maintenance

- Certifying test benches

- Easy to retro-fit.

- Exceptional communication & 4.000 test memory.

- Alarms for contamination levels

- Alarm for water

- Alarm for temperature

Recent Comments