Breathers

Storage

Filtration

Visual Analysis

Condition Monitoring

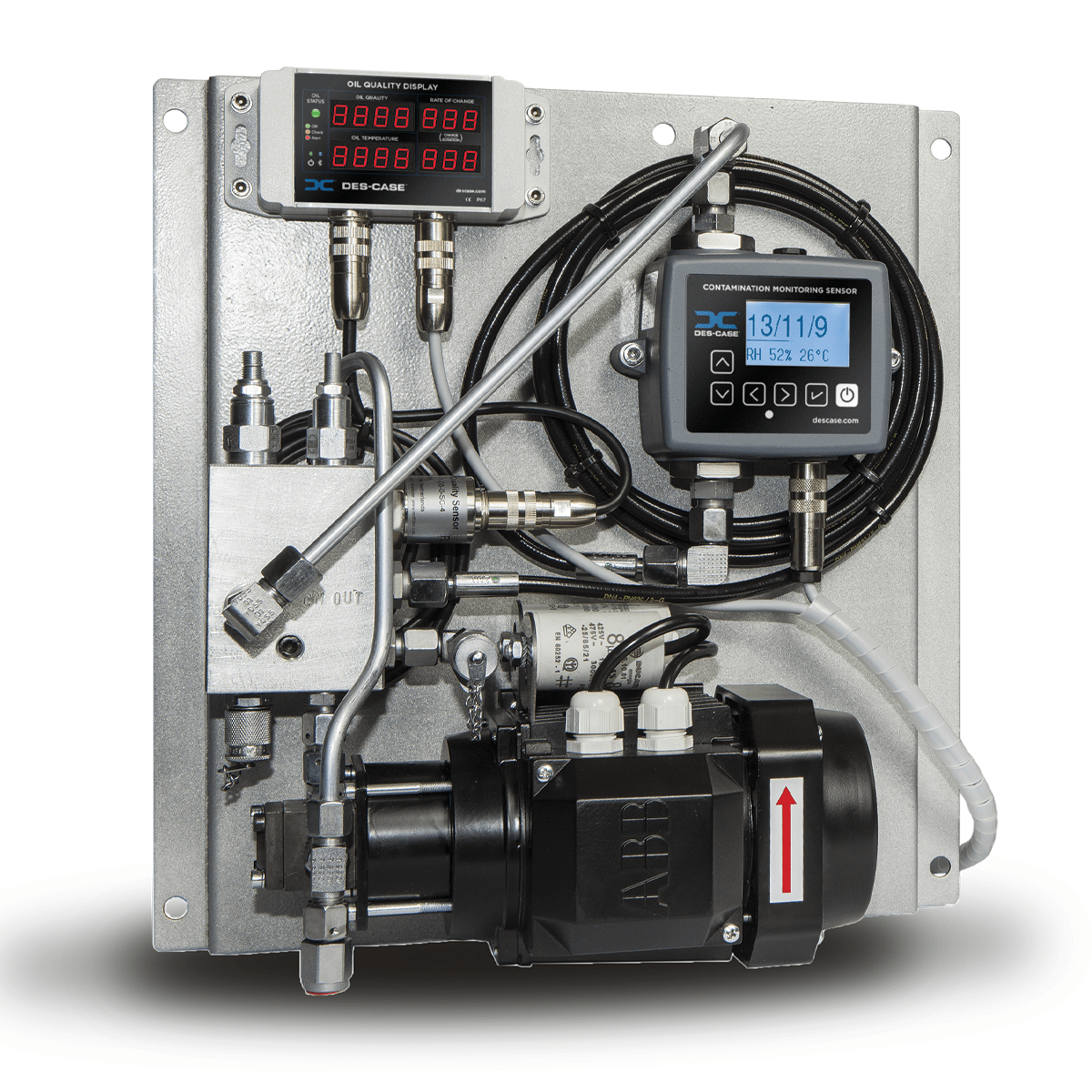

RMF Systems

Who We’ve Helped

Know Where to Start?

What We’ve Learned

Environmental Impact

A well executed reliability program extends the life of industrial lubricants and reduces enviromental footprint.

Increase Uptime

Maintaining clean oil can extend equipment life as much as 2-5 times.

Increase Profitability

A proper lubrication program can save 40% of a plant’s typical maintenance cost per year on lubrication related failures.

Explore Our Learning Center

Xcel Energy – Moving Towards Predictive Maintenance

One of the company’s oldest power plants, Black Dog Generating Station in Burnsville, Minnesota, has burned coal for most of its 65-plus years of producing electricity for Upper Midwest customers. In 2015, Black Dog transitioned to a clean-burning natural gas facility with a combined-cycle unit and a simple-cycle natural gas turbine.Need Assistance

Looking for additional information or want to move forward with your reliability program?